Do You Know the Difference Between Raw Lumens vs. Effective Lumens?

LED lamp output values (Lumens) can vary dramatically depending on which values are being quoted. The following information may assist in selecting the right product for the right application.

Raw Lumens

This is a measure of the theoretical output of a light. Raw Lumen output is calculated by multiplying by the theoretical rated output of the LEDs by the number of LEDs in the lamp.

Example:

8 LEDs rated at 100 Lumens per watt

8 x 100 = 800 Raw Lumens

Effective Lumens

This is a measure of the actual output of a light. The Effective Lumen output takes into consideration electrical and real world losses (ex. thermal, optical, and assembly), so it is a better representation of the useful visible light that is actually produced.

Example:

Raw Lumens = 800

Thermal, Optical & Assembly Losses = 40% (of Raw Lumens)

800 – 320 = 480 Effective Lumens

What do you mean by Thermal Losses, Optical Losses and Assembly Losses?

There are inherent losses associated with any lamp (LED, Halogen, HID or Incandescent). The main losses are related to 3 items: Thermal Losses, Optical Losses and Assembly variation.

Thermal Losses:

LEDs produce less light as they get hotter and generate a tremendous amount of power in a relatively small area. As the LEDs are powered for longer and longer periods of time, they typically get hotter and hotter depending on the thermal management system. It’s not unusual for LEDs to reach over 100ºC.

The greatest challenge is thermal management of LEDs. LED manufacturers typically measure the light produced by their LEDs after 25 milliseconds (ms). That is equivalent to a flash bulb. It gives a Lumen number that is the absolute maximum value.

For vehicle applications, most specifications require that the lamp be measured at 10 and 30 minutes to make sure that the LED temperature has stabilized. This will result in the LED producing 10 – 20% less light than it’s advertised value.

Optical & Assembly Losses:

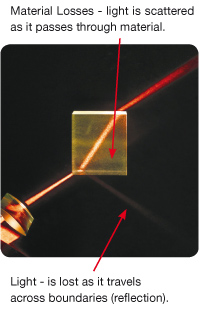

As light travels through an object (such as a lens), it loses intensity depending on the clarity of the material. This is due to inherent losses internal to the material and to losses at the boundary of the part as the light travels from air, through the lens, and back to air.

These losses are present whether the light source is an LED or a bulb. The losses associated with the lens material and optics can vary from 10 – 20%.

There are also losses associated with assembly and manufacturing variation. The LED output varies as the assembly tolerances may diminish the overall performance from theoretical LED maximums.

Simply adding the expected values of the LED light sources together will never result in a lamp that shines that amount of light on the ground.

The original article is: https://www.jwspeaker.com/blog/raw-lumens-vs-effective-lumens/

Raw Lumens

This is a measure of the theoretical output of a light. Raw Lumen output is calculated by multiplying by the theoretical rated output of the LEDs by the number of LEDs in the lamp.

Example:

8 LEDs rated at 100 Lumens per watt

8 x 100 = 800 Raw Lumens

Effective Lumens

This is a measure of the actual output of a light. The Effective Lumen output takes into consideration electrical and real world losses (ex. thermal, optical, and assembly), so it is a better representation of the useful visible light that is actually produced.

Example:

Raw Lumens = 800

Thermal, Optical & Assembly Losses = 40% (of Raw Lumens)

800 – 320 = 480 Effective Lumens

What do you mean by Thermal Losses, Optical Losses and Assembly Losses?

There are inherent losses associated with any lamp (LED, Halogen, HID or Incandescent). The main losses are related to 3 items: Thermal Losses, Optical Losses and Assembly variation.

Thermal Losses:

LEDs produce less light as they get hotter and generate a tremendous amount of power in a relatively small area. As the LEDs are powered for longer and longer periods of time, they typically get hotter and hotter depending on the thermal management system. It’s not unusual for LEDs to reach over 100ºC.

The greatest challenge is thermal management of LEDs. LED manufacturers typically measure the light produced by their LEDs after 25 milliseconds (ms). That is equivalent to a flash bulb. It gives a Lumen number that is the absolute maximum value.

For vehicle applications, most specifications require that the lamp be measured at 10 and 30 minutes to make sure that the LED temperature has stabilized. This will result in the LED producing 10 – 20% less light than it’s advertised value.

Optical & Assembly Losses:

As light travels through an object (such as a lens), it loses intensity depending on the clarity of the material. This is due to inherent losses internal to the material and to losses at the boundary of the part as the light travels from air, through the lens, and back to air.

These losses are present whether the light source is an LED or a bulb. The losses associated with the lens material and optics can vary from 10 – 20%.

There are also losses associated with assembly and manufacturing variation. The LED output varies as the assembly tolerances may diminish the overall performance from theoretical LED maximums.

Simply adding the expected values of the LED light sources together will never result in a lamp that shines that amount of light on the ground.

For example: the below is Qeedon's headlights

DOT Version-Raw Lumen Output: 4500 (High Beam); 2100 (Low Beam)

Except the losses, the DOT Version-Effective Lumen Output-2700 (High Beam); 1500 (Low Beam)

ECE Version-Raw Lumen Output: 2600LM (High) 1350LM (Low)

Except the losses, the ECE Version-Effective Lumen Output-1600 (High Beam); 1000 (Low Beam)

The original article is: https://www.jwspeaker.com/blog/raw-lumens-vs-effective-lumens/

评论

发表评论